How Marble Granite and Natural Stone Goes from Quarry to home villa hotel hospital and projects Flooring Elevation Decoration and Countertop

One of the best things about Marble Granite and Natural stone countertops, flooring Elevation Decoration. One of the best things about Marble Granite and Natural stone countertops flooring Elevation Decoration is that they come straight from the earth. These Marble Granite and Natural Stone materials are taken from the ground and then crafted into something that looks amazing in your home villa hotel hospital and projects or garden. But, have you ever wondered how this process works?

is that they come straight from the earth. These Marble Granite and Natural Stone materials are taken from the ground and then crafted into something that looks amazing in your home villa hotel hospital and projects or garden. But, have you ever wondered how this process works?

We’ll take you through this process to help you understand how Marble Granite and Natural Stone other types of stone go from the earth to your home villa hotel hospital and project kitchen. Since we’ve got such impressive granite quarries right here in North Carolina, let’s focus on how Marble Granite and Natural Stone goes from quarry to Flooring Elevation Decoration and countertop.

Mining Marble Granite and Natural Stone from quarries

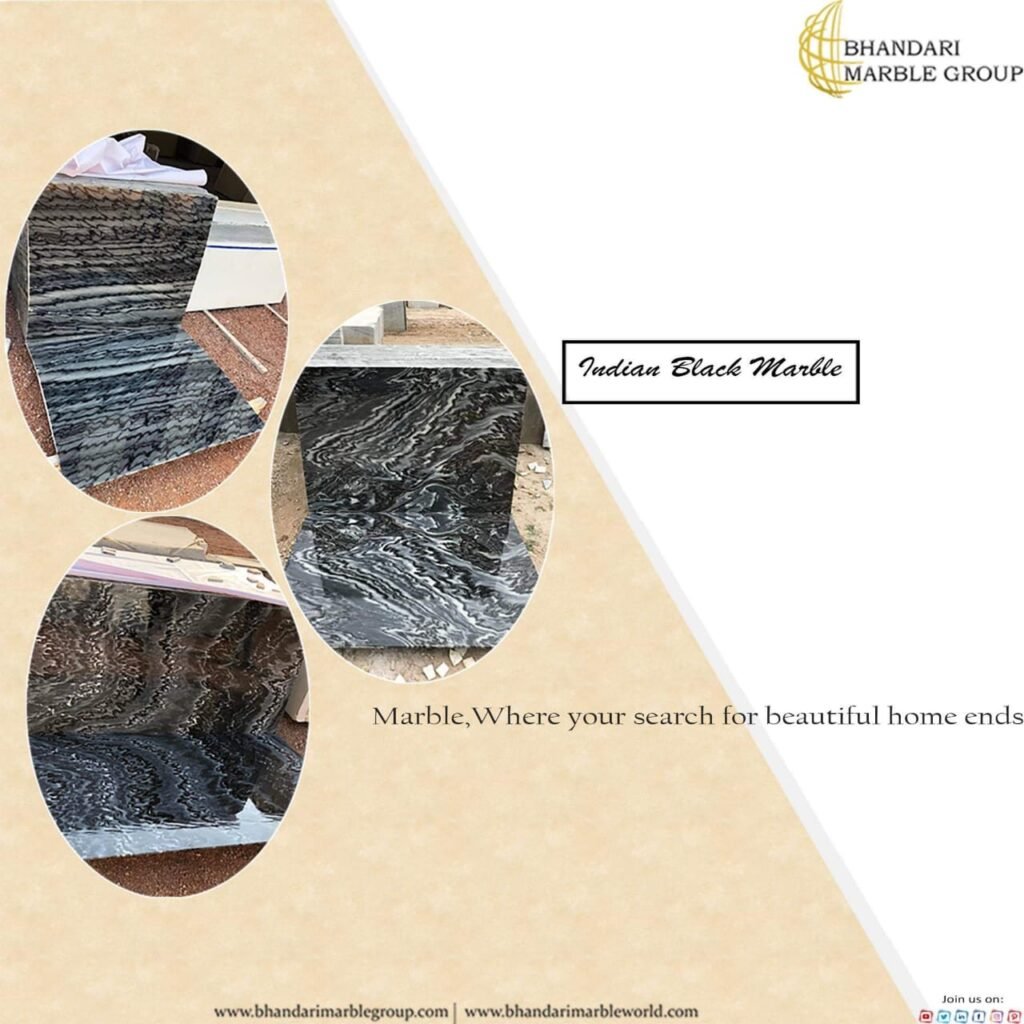

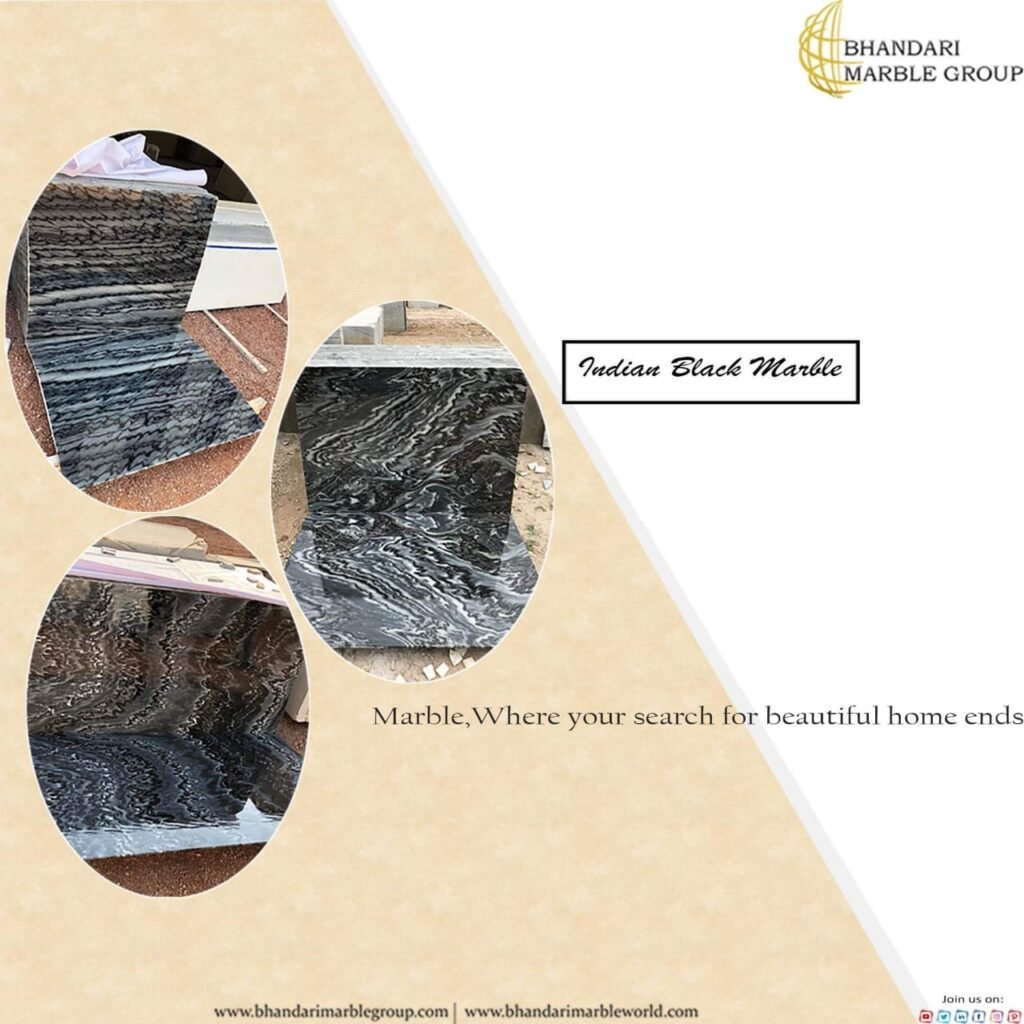

Marble Granite and Natural Stone are found close to the earth’s surface in locations called quarries. The stone is extracted or mined from these locations using drills and explosives. These techniques break large chunks of Marble Granite and Natural Stone away from the quarry so that it can be transported and used in a number of ways. Cranes and other machinery will be used to lift the granite and move it onto a truck so that it can be transported.

Processing the Marble Granite and Natural Stone

The Marble Granite and Natural Stone extracted from quarries are extremely unrefined, pretty far removed from what you ultimately get for your kitchen countertops. The chunks of rock must be transported to a factory or other facility where it can be processed and fabricated. Specialized machinery is required to cut the granite into smaller slabs. Diamond blades are the most effective equipment for performing this job.

Once cut, the Marble, Granite and Natural Stone slabs are polished to give them a nicer finish, as it will have come from the quarry with an extremely rough finish. Large machinery using polish pads complete this process. The finished slabs are then ready for distribution. Some providers will fabricate the granite in-house while others will have it shipped to them after fabrication is complete.

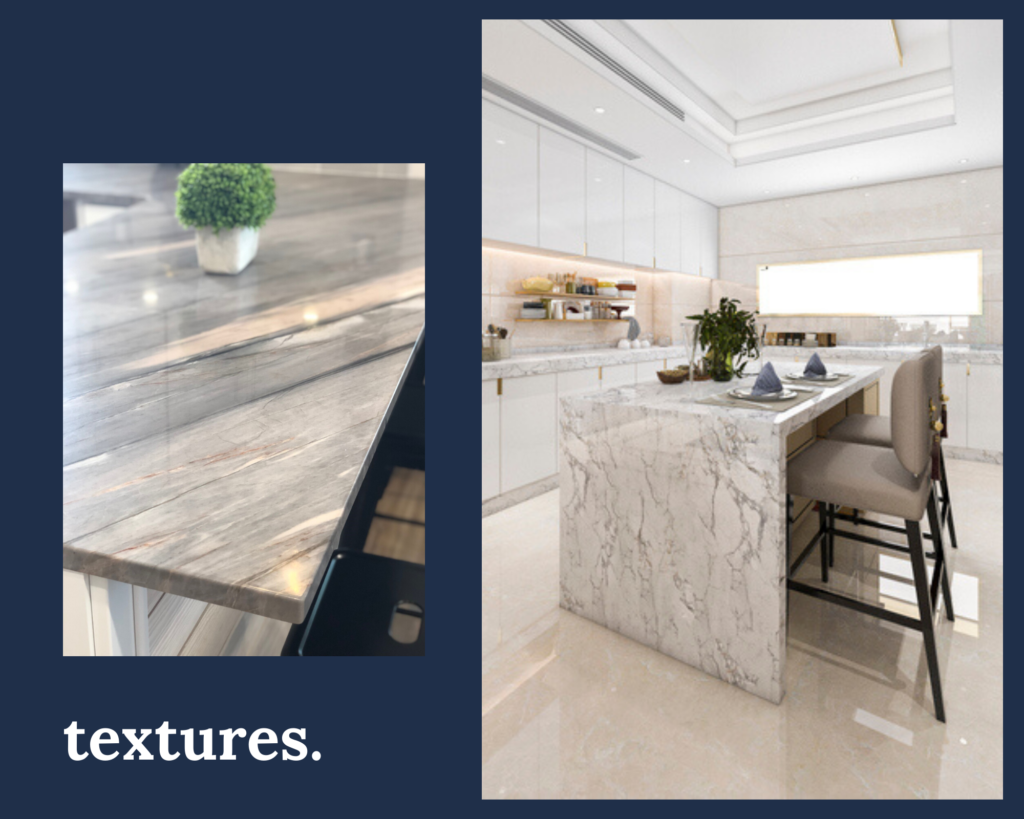

Marble, Granite, and Natural stone sellers can place these slabs in their showrooms for customers to browse and buy, but the process isn’t over yet. When someone buys Marble Granite and Natural Stone, one of the slabs will be measured and cut to the right size and shape for the countertops needed. Different finishes can also be applied to the Marble Granite and Natural Stone slab, such as a polished, honed, or matte finish.

An edge will also be applied to the stone, such as a square or beveled countertop edge to give it the perfect finishing touch. These Marble Granite and Natural Stone Flooring Elevation Decoration and countertops can then be installed in your home villa hotel hospital and project kitchens or bathroom for the final result. The Flooring Elevation Decoration and countertop may also be sealed to protect it after installation.

So, there you have it. A piece of Marble, Granite, and Natural stone from the ground meticulously finished producing the perfect surface for your kitchen or bathroom countertops. You can visit our website or Factory outlet showroom to view our granite slabs or get in touch to find out more about our natural stone Flooring Elevation Decoration and countertop.

Marble, Granite and Natural Stone Is Mined from our Quarry

The first step of making a Marble Granite and Natural Stone slab is to mine the raw granite materials out of the earth. Marble, Granite, and Natural Stone slabs are obtained from special sites that are known as quarries. Some of the most prolific quarries in the world are in far-flung locations, such as India. Using powerful machines, a mining company mines and blasts raw Marble Granite and Natural Stone out of the quarry.

Milling Machines Cut the Slabs

After Marble Granite and Natural Stone have first been mined out of the earth, it will be in a very rough form. After the mining process is complete, the Marble Granite and Natural Stone will be sent to a workshop to be transformed into slabs. A technician will use milling machines to cut and polish the Marble granite and Natural stone. Once milling has been completed, the slab will be between 7 and 9 feet long. When you visit us Marble Granite and Natural Stone showroom, these slabs are typically what you will be shown.

The Slabs Are Transformed Into Flooring Elevation Decoration and Countertops

After you have selected a slab that offers the color variations and patterns that are appealing to you, you will be ready to create your custom countertops. Your Flooring Elevation Decoration and countertop fabrication specialist will take measurements of your home villa hotel hospital and projects in order to cut the Marble Granite and Natural Stone to the correct shape. A template will then be used to cut the granite to size and the edges of the Marble, granite and Natural Stone will be shaped and finished.

ADD BY EXPERT AND EXPORT TEAM OF BHANDARI MARBLE GROUP. CONTACT US ON; 9672941111